The adage, “Necessity is the mother of invention,” has applied time and again to the Eden Prairie-based manufacturer and innovator of products in the audio/visual space. The genesis of its product line dates back to 1975, when Jerry Williams, an experienced engineer by trade, created a new wireless device to enable parishioners at his church to hear the pastor. As the company expanded its offerings in the ensuing decades to respond to new needs, Williams Sound became Williams AV (WAV). Which brings us to today. Led by president and CEO Brad Kautzer, perhaps WAV’s most important innovation was the re-invention the company undertook out of necessity for its survival.

Business management – Remaking a vision

WAV faced uncertainty during the pandemic. But in the face of adversity, WAV saw an opportunity to explore new supply sources and further refine its production floor operations.

Tariffs and COVID impact

COVID dramatically interrupted WAV’s supply continuity as the company relied heavily on electronic components being readily available, as well as China-based contract manufacturers to complement its Minnesota-based operations. Additionally, U.S. tariffs enacted in 2018-19 had a profound impact on product costs that made a wide range of products uncompetitive in a global market. WAV resolved these issues by re-engineering several key products and shifting high volume production to a Vietnam-based supply chain supported by a new strategic manufacturing partner. All of this was executed during the pandemic, which required extensive cross-functional efforts across the entire organization. This alleviated a significant cost pain caused by the tariffs and helped WAV stay ahead of the uncertainties that came about during COVID.

Another factor that contributed to WAV’s successful navigation through a year of worldwide business turmoil was its prioritization of existing resources on reliable technology and product offerings. Nothing showcased this better than WAV’s shift to providing communication technology to businesses that faced extreme communication challenges due to COVID protocols, notably the judicial and medical markets. Seizing these market opportunities helped establish the company as a leader in these spaces, deploying advanced technology solutions that could safely bring people back together and keep important economic and social systems running in a new way.

Re-evaluating production performance

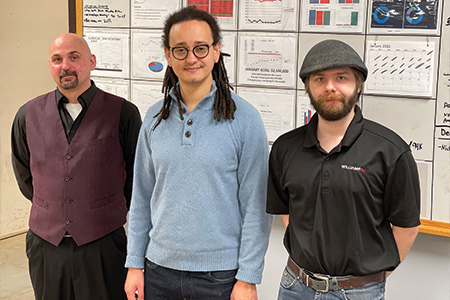

While the business world worked to right itself, WAV took the temporary market slowdown to re-evaluate its internal processes and look for opportunities to improve operating efficiencies and quality systems. With the leadership of production manager Tim Miller, manufacturing engineer Nick Richie, and quality manager Chris Clark, WAV underwent a wall-to-wall production evaluation and reset. This team worked together to make changes to the company’s operating principles and quality operating system so that its operations were more rigid, simple, and accountable to key business needs. The results were improvements in quality, efficiency, and cost reductions.

WAV incorporated the 5S lean manufacturing methodology: Sort, Set in order, Shine, Standardize, and Sustain. Using these five principles as the benchmark for continuous improvement on the production floor, the team set the stage for a trajectory toward sustainable success. In keeping with a new lean standard of operations, the management team worked with other employees to make additional significant changes, such as removing substantial amounts of outdated testing equipment and unused machinery to free space for a complete reconfiguration of the production floor.

The quality operating system also received a thorough review. Electrostatic discharge (ESD) is a major concern in an electronics-based manufacturing company. ESD can shorten the lifespan of electronic products or even render them unusable. WAV’s management team evaluated the risk level in the production area and found it to be unacceptably high. To ensure high quality, reduce repairs, and reduce the level of returns and malfunctions, the company implemented ESD controls. This demonstrated to customers and employees WAV’s commitment to safety and consistently reliable products. Other improvements included a redesign to the production floor to comply with OSHA requirements and improve workforce flow, an important step to eliminate waste and enhance efficiency.

Communication is key

The team recognized that many issues were rooted in communication, documentation, and procedure controls. A major part of the solution was in standardizing these measures. Employees then had a clear chain of procedures and communication to follow to efficiently solve problems as they arise, instead of allowing them to grow and affect other areas of the workforce. Standardizing communication methods also gives workers confidence that orders will be addressed in a timely, attentive manner.

Additionally, WAV implemented two important aspects of communication: daily stand-ups and enhanced documentation/standard work. The day starts with a 15-minute stand-up meeting where employees and production operators meet to review daily goals and communicate issues that could result in production delays. These morning meetings are held on the production floor and include representatives from each of the functional areas as well as the full production team. The team discusses issues that could impact daily output and resolves any critical customer needs. The meetings provide visual management, accountability to gain alignment across all business functions daily, and the venue to recognize employee accomplishments.

Prioritizing quality and workers

Quality Assurance is a necessity to prevent mistakes and defects in manufactured products and focuses quality management on fulfilling orders. Using the new procedures also gave employees guidelines, and consequently the confidence that they are delivering standardized, high-quality products. Quality Assurance improves employee engagement, helps inspire pride and trust, and encourages accountability because everyone has a responsibility to ensure quality products.

Turning inward to find improvements and encouraging workers to take ownership of quality control and communication helped WAV become an industry leader, not only measured by its products but by its employees. Brad Kautzer and the WAV leadership team actively foster a culture of innovation, quality, and service, which has positively impacted the company’s bottom line. WAV just finished 2021 recording new highs in cost-savings, revenue, and profitability.

COVID starts a new era

By offering such a wide range of products, WAV embraces the goal of inclusivity and innovation. WAV further extended its offerings to include a secure digital communications device called Digi-Wave. Since the beginning of the pandemic, trials and court-hearings were delayed, as courts worked to find effective ways to communicate while balancing constitutional rights and privacy with safety and public health risks. Digi-Wave provided the solution that courts were looking for at a time when it was needed most.

Because of the risk of COVID-19 infection, courtrooms had to provide adequate social distancing. Along with masking requirements, this limited the number of people who could occupy a room. It also affected how attorneys could communicate with their clients, the judge, and the jury. Digi-Wave solved these issues by eliminating the need for a close-quarter encounter while maintaining secure communications channels for privacy. Digi-Wave’s secure audio system allowed the defense and prosecution to speak privately while maintaining a safe distance. They could also speak with the judge on a private channel when needed. Additionally, WAV’s Annotation Pro+ product enables attorneys to highlight key pieces of evidence, improving communications among those in the courtroom. Thanks in part to WAV’s technology, the large backlogs of courtroom hearings are showing signs of easing.

Historic innovation

After solving the problem with his church, founder Jerry Williams developed the “Pocketalker,” a personal sound amplification device. The Pocketalker amplifies sounds closest to the listener while reducing background noise. WAV offers several models and configurations of the Pocketalkers to meet the needs of people requiring hearing assistance, such as improving their ability to engage in communications in nearly any environment.

Williams pioneered the assistive listening device space with his Pocketalker. Over the course of the next three decades, Williams Sound continued to be an industry innovator by establishing multiple products and technologies for assistive listening devises and incorporating various methods of audio transmission such as FM, infrared, digital, and even induction loop systems, which transmit directly to users’ hearing aids. In addition, WAV’s Wi-Fi technologies allow for streaming audio directly to a user’s personal smartphone or tablet through Wi-Fi transmitters and offer secure encrypted communication.

Focus on annotation

Not a company content with being idle, Williams Sound took a big step in expanding its offerings in 2017 when it acquired Pointmaker. Pointmaker was the leading provider of hardware and software for the growing video annotation market, and the acquisition signaled Williams Sound’s foray into the larger professional audio/visual market. Williams built on and enhanced Pointmaker’s video technology, renaming it Annotation Pro and Annotation Pro+. The Annotation Pro products increased the company’s market opportunities by allowing individuals to draw a freehand sketch over live or still video images. This technology is frequently used in courtrooms, classrooms, corporate presentations, sports, and weather broadcasts. “The Pointmaker acquisition opened an opportunity to combine Williams Sound’s technological knowledge and direct it to the expanding video market,” says Kautzer. Confident in its place at the forefront of audio/visual communication systems, the company changed its name to Williams AV (WAV) to reflect its broader offering in the market with more video-centric innovations.

ADA provides opportunities for new hearing technologies

The Americans with Disabilities Act of 1990 opened the opportunity for WAV to make a real, tangible difference in the lives of millions of people in the United States. According to the legislation, the ADA requires covered employers to provide reasonable accommodations to employees with disabilities — including hearing impairment — and imposes accessibility requirements on public accommodations. WAV’s technologies not only assist people with hearing impairments, but the company’s products also ensure employers and businesses meet ADA regulations. The company’s website even offers an ADA calculator to help businesses find the number of audio receivers the ADA requires for a space. It is this type of forward-thinking and website accessibility that builds relationships between WAV and its clients. An exceptional team is eager to assist with both their consumer products as well as professional AV products. Inclusion and engagement are not just a slogan; they are a mindset.

New offerings to meet new demands

By offering such a wide range of products, WAV encompasses the mantra of inclusivity and innovation. In today’s world, where communication is an integral part of being successful, WAV has the technology to improve communication across language, culture, and ability roadblocks. In 2019, WAV introduced the next generation of assistive listening devices. The company rolled out a series of devices to fulfill a demand in professional settings to broadcast sound through Wi-Fi, FM, and Bluetooth systems with its Dante Assistive Listening System.

Guided tours

WAV uses its portable technology to offer audio solutions for guided tours and intercoms in commercial settings. From Wi-Fi, FM, hearing loop technology, and infrared, WAV technology has the capability to meet a variety of needs, from walking tours to commercial presentations.

Interpretation and translation

In a world that is becoming increasingly interconnected, language and location barriers are affecting business worldwide. WAV helps break down those barriers by offering AI-based (artificial intelligence) interpretation and human translation services. This was a key component to helping companies adapt to the COVID environment in which Zoom meetings became more prevalent.

Incorporating artificial intelligence

COVID also spurred further development in new AI technology. In a world that is increasingly interconnected, language and hearing barriers can have a real impact on business. WAV saw this as a real challenge and began incorporating AI into its product offerings. WAV was an innovator in the truest sense, becoming the first company in the industry to use AI with its Caption Assist and Convey Video as a viable option when humans are not available for interpretation, or when human interpretation doesn’t fit within the scope of a company’s budget. This emerging field has many professional applications and lends itself to today’s global economy and international markets. According to WAV, a computer can caption live audio into text and even translate it. It works using WAV devices that apply AI-based captioning and translation and then output the captioning and/or translation directly to a display as an overlay. The video, image, or presentation that the audience is viewing will still show on the display along with the captions or translated subtitles. Currently, the device can translate over 109 languages and 28 dialects.

Kautzer explains, “Utilizing leading-edge AI-based technology, Convey Video enhances communications across boundaries and languages. Whether it is enhancing comprehension in higher education, translation and recording in judicial, medical, and law enforcement, or improving global business communications effectiveness, Convey Video does what no other solution can offer. Using the latest available technology integrated into one package, Williams AV offers solutions to meet a range of uses.”

Forging ahead

AI-based innovation is the latest example of how WAV recognized the value of emerging technology and incorporated it into existing devices and products. This forward-thinking mentality highlights the importance of staying abreast of industry changes as our technology-driven world continues to evolve faster and faster. With many companies struggling to stay relevant, WAV certainly accomplishes this, and then some. Looking at each emerging technology as an opportunity to innovate is a lesson many manufacturing companies can learn from, whether it is through automation, artificial intelligence, streamlining production floor operations, or re-evaluating supply chain management operations.

…

Featured story in the Spring 2022 issue of Enterprise Minnesota magazine.