It can be oddly satisfying to watch a Toyota Camry get crunched to a fraction of its original size with the power of hydraulics. And if you thought that was the end of that Camry’s usefulness, think again.

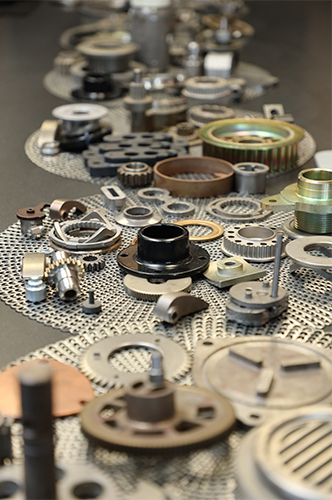

The metal from some of those cars gets reused in a way that, again, is oddly satisfying. The mangled metal parts go through a high-temperature, high-tech recycling process that, in the end, produces a flour-like, highly purified metal powder. One, and only one, company in Minnesota for decades has been using that powder to produce metal components for everything from snowmobiles to medical devices.

From metal to metal

FMS Corporation, founded in 1946 by Fred Sweet and now led by his grandson John, has carved out a unique niche in Midwest metal parts manufacturing as the state’s only customized powder metal manufacturer. With a highly specialized process and deep family roots, the company is working to diversify its customer base across the five-state region while preparing the next generation to take the reins.

At the center of FMS’s operation is a process many outside the industry misunderstand: powder metallurgy, or PM. Not to be confused with powder coating, powder metallurgy is a way of forming metal parts by compressing the fine metal powders in a die, then fusing them together in a high-temperature furnace. It’s a process that produces extremely precise parts with little waste, allowing manufacturers to avoid expensive machining or casting.

“PM is definitely a niche industry in North America, with most companies concentrated in Pennsylvania and focused on supplying the automotive industry,” says John Sweet, president of FMS. The powder metal industry’s automotive focus has left the Midwest region ripe for mining new customers.

That uniqueness has served the company well for nearly 80 years. FMS has supplied parts for Polaris, Graco, and other major manufacturers, often producing components that end up in products Minnesotans know well — snowmobiles, industrial sprayers, agricultural equipment, etc. The company’s versatility and ability to produce high-quality, cost-effective parts have kept it competitive in a global market where scale and efficiency often determine survival.

Extending its reach

Still, Sweet knows the company can’t afford to rely too heavily on a handful of big-name customers. The cyclical nature of industries like powersports can create peaks and valleys in demand, and FMS has been working with Enterprise Minnesota to sharpen its sales and marketing approach. The goal: to grow awareness of FMS’s capabilities and bring in new business across Minnesota and surrounding states.

“We’re trying to diversify our customer base,” Sweet says. “We’ve had long-term relationships with some great companies, but to really strengthen the business, we need to make sure more people in our region know who we are and what we do.”

Amy Hubler, an Enterprise Minnesota business growth consultant working with FMS, says she’s been strategizing extensively with FMS to do just that.

“In our work together, we did a deep dive into the company’s different customers and landed on one to two priority target segments that are a logical fit for FMS and offer the most opportunity as well,” Hubler says. “This is driving the marketing and sales strategy — knowing who they are going after, how they can best reach them, and what the optimal message is. FMS is taking that strategy and partnering with a digital agency to bring it to life.”

That’s no small task in an era when manufacturers are bombarded with pitches from suppliers worldwide. But FMS believes its story — a mix of specialized expertise, generational stewardship, and steady reinvestment — sets it apart. Geography helps, too. Most of FMS’s customers are in Minnesota and the broader five-state area, a geography Sweet believes is both practical and strategic. Proximity means faster turnaround times, fewer logistics headaches, and the ability to build strong relationships with engineering teams and buyers.

At the same time, FMS is realistic about the challenges ahead. Labor shortages, rising input costs, and global competition remain stubborn headwinds. Powdered metal itself is subject to price fluctuations tied to global steel markets, and customers are constantly pushing for cost savings. To compete, FMS has leaned on its efficiency and ability to engineer solutions that reduce waste and shorten lead times.

Over the past decade, the company has invested millions in new presses, furnaces, and secondary equipment so its plant can handle larger volumes, tighter tolerances, and more complex geometries. Those investments have allowed FMS to pursue work it couldn’t have a generation ago.

“Customers are always going to look at price,” Sweet says. “But if we can show them that our process gives them a part that performs better, costs less to machine, and gets to them on time, that’s a compelling story.”

That story is what FMS hopes to tell more broadly as it expands its marketing efforts. Sweet acknowledges that the company has historically let its work speak for itself, relying on word of mouth and long-term relationships. But as the industry evolves, he sees the need to be more proactive in showcasing FMS’s capabilities.

“We developed a two-pronged approach: education on powder metal manufacturing for those who may not know anything about it and building awareness of FMS as a key powder metal partner for those who are already familiar with the industry,” says Hubler. “It’s paying off as more of the marketplace is being exposed to FMS and learning about who they are, what they do, and most importantly, what sets them apart. That leads to increased requests for information and quote requests.”

“Opportunity is out there,” says Sweet. “The more people understand the advantages of powder metallurgy, the more we can grow.”

A foundation for the next generation

“We’re not standing still,” Sweet says. “Every generation of leadership here has made big investments to make sure we’re ready for what comes next. That’s how we’ve stayed in business this long.”

That generational theme is central to FMS’s identity. Sweet’s son Luke, a St. Thomas University grad, is the fourth generation to step into the business, carrying forward a tradition of family ownership that Sweet says is increasingly rare in manufacturing.

“It’s something we’re proud of,” Sweet says. “There aren’t many companies left with three generations who have run the place and a fourth on the way. It gives our employees and customers confidence that we’re in this for the long haul.”

For FMS, growth doesn’t mean chasing every opportunity or abandoning its roots. It means deepening relationships in the Midwest, continuing to invest in technology, and passing down the values that have kept the company strong for nearly 80 years.

“Family ownership means you think in decades, not quarters,” Sweet says. “That’s been our approach since my grandfather started this company, and it’s how we plan to keep moving forward.”

Return to the Winter 2025 issue of Enterprise Minnesota® magazine.