MTG, Inc. and Lethiguel USA recently received ISO certifications.

The timing was right, Marcus Amble says, to get ISO certified. Last year, he and his wife Trista bought Minnesota Tool Group, Inc., a precision grinding company that specializes in cylindrical OD/ID and surface grinding. Amble’s father, Marc, had started the company in 1998.

After rebranding to the company’s abbreviated name — MTG, Inc., developing a new logo, and expanding their web presence, they decided to pursue ISO certification.

“We’re always looking for more customers and expansion,” Amble says, and ISO certification would open up the company to work with more and larger clients.

MTG’s standards were already high — all of its machinists also qualified as quality inspectors. The company was basically ISO compliant but not certified.

“Our key markets include high-end medical and aerospace mission-critical components where quality and precision are non-negotiable,” Amble says. When working with expensive components that will become surgical tools, airplane parts, and elements for the U.S. Department of Defense, the quality has to be there. The company had been “grandfathered in” by its clients, but to expand, ISO certification was essential.

MTG’s team of eight worked through the ISO process with Enterprise Minnesota business growth consultants Keith Gadacz and Amy Thimmesh. Amble was pleasantly surprised by how closely MTG’s management system adhered to ISO standards.

Within about two weeks of MTG’s ISO audit in May, Amble says, “we were contacted by an aerospace OEM and asked about our ISO certification. We wouldn’t even have received that phone call without it. It reaffirmed that we’d made the right decision.”

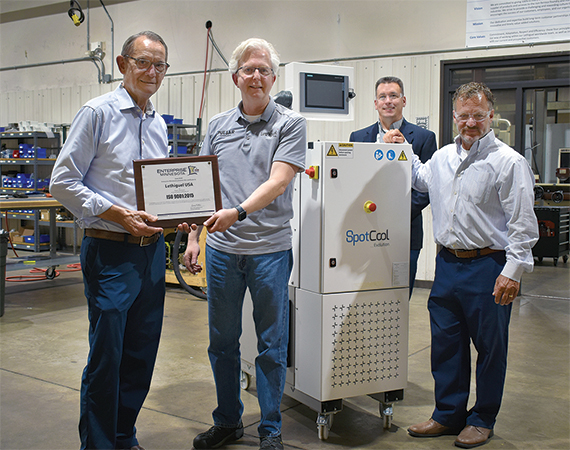

Lethiguel USA

Lethiguel USA in Rogers, Minn., produces components for the tool and die industry, specifically for high pressure die casting. General Manager Mark Steen started with the company in 2018, when it was Midland Technologies. In 2021, Lethiguel, a European company based in Lyon, France, acquired the company. Midland already had an established product line, staff, and facilities for manufacturing here, and Lethiguel wanted to get into the U.S. market.

Steen had been considering ISO certification as a good step to expand the company’s customer base. When a particular customer in North America required them to be ISO certified, that was the nudge to start the process.

“I think ISO adds a level of discipline to the whole manufacturing process,” Steen says. He sees it as an accountability feature.

The company already had good routing of the manufacturing process and good documentation, but, says Steen, “we didn’t really have certain management tools in place formally. We solidified our KPIs, submitted the SWOT analysis, and tracked the different critical aspects of the business so we could show what we’re doing.”

Through a “very good and thorough audit,” he says, “there was only one minor infraction, and with Keith’s help we got it taken care of, submitted the paperwork, and everything fell into place.”

Return to the Winter 2024 issue of Enterprise Minnesota® magazine.