In 2007, Mike Jensen had a chance to buy into Gauthier Industries, the Rochester-based custom metal fabricator where he’d worked for a decade. It was a huge opportunity for the then 37 year old, and horrible timing.

“Little did we know the great recession was coming,” he says. When the economy tanked, Gauthier’s leaders faced the agonizing task of laying off 30% of its workforce of nearly 100. “It was one of the most difficult times in my career,” Jensen says.

His business partner, Terry Grendahl, remembers spending a week with Jensen and other company leaders, going through the business department by department to decide which jobs could be eliminated. All wages were frozen and company executives took a pay cut, too, to help the company get through the downturn.

Employees learned of the layoffs at an all-hands meeting the following Monday. “Everybody knew,” Grendahl says. “There just wasn’t enough work to go around.” But after the news had been delivered, Jensen’s biggest concern was that no one get injured on the job that day. He asked supervisors to watch out for workers who might be emotionally distraught and let people take a break or go home if they needed to. Everyone worked safely, and Gauthier struggled through the recession but came out of it strong. Today it’s back up to 82 employees and sales of $15 million annually. “We endured very low sales months,” Jensen recalls, “but we never lost profitability.”

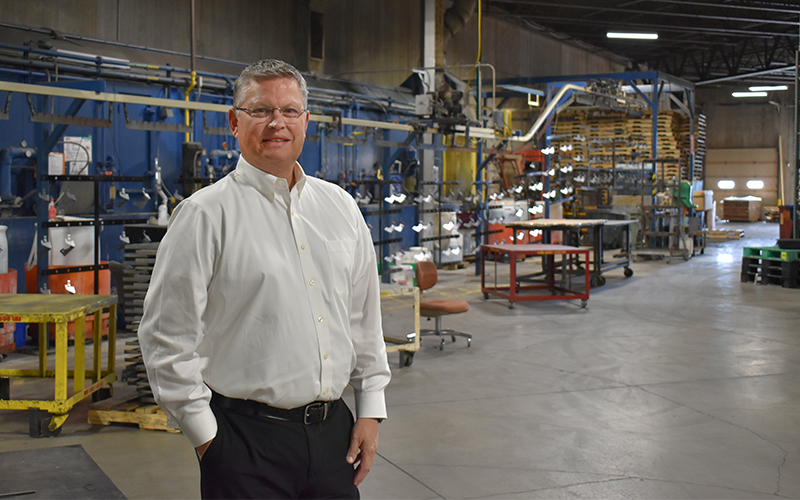

Empathy for employees — Jensen started his career at Gauthier on the paint line — coupled with an analytical approach, an amiable disposition, and a clear sense of a leader’s role have been hallmarks of Jensen’s career at Gauthier, a nearly 80-year-old custom metal fabricator. This combination of skills and personality, coupled with a drive to learn, has made Jensen a leader in manufacturing statewide and poised Gauthier for growth into its ninth decade.

The temp

If you’re getting a plant tour from Mike Jensen, be sure to bring your track shoes.

Jensen can whip through the 100,000-square-foot plant where he’s worked since the mid-1990s in record time. He shows where the company’s semi-truck loads up every morning for product deliveries to the Twin Cities. During a swing past the laser cutting area, he proudly describes the purposefully small area set aside for product that did not meet quality requirements. And then he moves to the new screen-printing machine that offers expanded services to Gauthier’s 250 clients, making parts for everything from golf carts to combines to large compressor housings. He lingers awhile to explain the powder-coating process. This is where he started at Gauthier, as a temp.

Jensen’s father died when he was only 18. “I was forced to grow up quickly and become a leader at a young age,” he says, “to help my mom, to be the oldest brother who would help others.” A desire to be close to family brought Jensen back to Rochester after college at St. Cloud State University, where he got an industrial engineering degree and aviation minor. He spent a few years as a supervisor at UPS and then reconnected with Tom Gauthier at a Rochester job fair. Tom’s father, Emil, founded the company in 1946 initially to manufacture the “Rochester Plastic Needle,” a breakthrough in the administration of intravenous fluids. In the 1960s, it was the first firm to manufacture a home hemodialysis machine. It moved into custom metal fabrication in the late 20th century. Currently a full-service job shop, it does metal fabrication, including tool and die, welding, machining, silk screening, powder coating, and assembly.

Jensen grew up as friends with Gauthier’s son and was intrigued by the offer to run the paint line for a three-month period. While Jensen had a full-time opportunity at a company 30 miles away, he took the temp job instead, thinking it had more potential, even though it was for less salary.

The paint line operated in a separate building and struggled with everything from long lead times to excessive rework. “They asked me to improve on some difficult things,” Jensen says. So, he began by working on the line with employees to understand where the bottlenecks and pain points were as well as the challenges the employees faced.

“I had to earn their respect,” he says. “We worked on these issues and had some good success with buy-in from employees.”

A few years later, Jensen was production manager when he and Grendahl, then the engineering manager, were charged with addressing one of the company’s biggest barriers to growth: very long lead times throughout the company. Many projects took up to six weeks from order to product out the door. One factor in the slow work times was actually an over-emphasis on how many pieces machine operators finished per hour, what they called “making the rate,” Grendahl says. Employees neglected things like sharpening tooling and organizing pieces in order to make the rate. Jensen decided to add some indirect help by putting a supervisor in charge of organizing the tooling, sharpening it, and pulling tools for the next job so it’s ready to go. “We kept the machines running, reduced set up time, and had less gap time between items,” Jensen says. Those changes significantly improved lead times. Today, Gauthier can turn repeat orders around in two weeks, and new business in about three.

“I’ve learned that we have to take a very transparent approach with our employees,” Jensen says. “What we talk about in our staff meetings has to make it to the supervisors, has to make it to the employees, so they know what’s going on. There’s nothing to hide.”

Taking a team approach has also led to greater employee retention, he says, a significant accomplishment in a town where Mayo Clinic, Minnesota’s largest employer, has 14 times the number of jobs as the second largest employer in town.

The youngest guy in the room

Jensen, who has a 51% stake in the business, is the fourth owner of Gauthier. He and Grendahl bought the business from Dave Kocer, who had bought it from the Gauthier family. Today, Kocer sits on its board of directors. Having Grendahl as a partner felt necessary to Jensen.

“I needed Terry to be part of it,” he says. “It would have been difficult if I had this all to myself.” Grendahl attributes the success of their on-going partnership to having complementary skill sets. Jensen gets people; Grendahl digs numbers. “He’s very even tempered,” says Grendahl. “He’s always looking for everyone’s input before decisions are made.”

As a young owner and executive, Jensen knew what he didn’t know. “I had the skills,” he recalls, “but I needed more.” To get that, he joined an Enterprise Minnesota regional Peer Council for company owners. The southeast Minnesota group meets monthly for peer-to-peer discussions, plant tours, and occasional speakers.

“It was single-handedly the most important thing I’ve done in my career,” Jensen says. “The people in the Peer Council had years of experience. When I first got there, I did a lot of listening. I didn’t have a lot of input for others because I was listening so much.”

As confidential forums, the Peer Councils enable executives to exchange information and ideas as well as present problems to others who occupy the same position you do, says Bob Kill, president and CEO of Enterprise Minnesota.

“The corner office can be a solitary place,” says Kurt Bear, an Enterprise Minnesota business development consultant. Working with fellow owners, Jensen began to understand more deeply the issues relating to personnel, labor, banking relationships, and all the factors that can help or hinder a business.

Finding the right fit for your company in areas like law, accounting, and insurance was among the issues Jensen took home with him. “I came into this company with all these prerequisites in place,” Jensen says. “We had a bank. We had accountants. We had insurance companies that covered us for health, property, and casualty. I had to decide whether it was the right choice to keep everything in place.”

Peer Council meetings present opportunities for guest speakers, including insurance brokers on occasion, which is when Jensen began shopping the company’s insurance — something that had not been done in years — and discovered they had been overpaying. Now they shop insurance annually. Eventually, they changed banks and accountants, too. “There are certain types of services that work better with small businesses than large ones,” he says. “Big accounting firms don’t always work well with small businesses, and we had a big accounting firm and bank.” They found another accounting firm and smaller bank that better suited Gauthier’s size and interests, saving them money and getting them more tailored advice.

“I didn’t change everything,” Jensen says, “but I certainly wanted to look at what we could do to save some money.” As an employee profit-sharing company, Gauthier’s employees “understand that if they do their job efficiently and with quality, there will be something there for them at the end,” he says. “Whatever we can do on this side of the wall to help, we’re going to do.”

To ensure they hire and retain good employees, Gauthier relies on a multi-pronged approach. For five consecutive years, from 2013-2017, the company was named a Best Place to Work in the region by Workforce Development, a nonprofit agency in southeast Minnesota. Gauthier works through agencies to recruit new employees. “That way we can measure things like attendance and work ethic,” says Jensen, “and if everything works out, we’ll on-board them in four to five months.”

A program with high schools in Rochester and nearby Byron, where Jensen lives, exposes students to career opportunities in the company. Student interns get paid to do simple assembly or packaging two hours a day for four days a week or part time during the summer. Several have joined the company after high school. Current employees are cross-trained as much as possible.

“Working here, you don’t become somebody who has only one skill,” Jensen says. “They have flexibility, and in a job shop you need to have that. It’s essential to connect our youth with manufacturing early in their development. They may see it as an opportunity someday.”

One of Jensen’s mantras is: “If you bring me a problem, please bring me a solution as well. I’ll tell you if I agree with it or not, but please bring me a solution.”

“Every single person here is important to the company,” Jensen adds. The company shows appreciation by recognizing employee birthdays and work anniversaries along with distributing profit-sharing checks at the company Christmas party. “I encourage employees to improve and expand their capabilities so they can move up in the company. Ideally, we want to promote from within.”

Shifting sales strategy

Gauthier has worked with Enterprise Minnesota on lean manufacturing and leadership essentials as well as attaining ISO 9001 registration, which makes bidding on projects easier because the certification attests to a commitment to quality. “For a customer quality audit, we’re told they can fast forward through numerous audit sections once you are certified,” Jensen says.

Prior to the COVID pandemic, the company made a dramatic shift in its approach to sales. The company had been working with independent manufacturers’ sales representatives, and needed to rethink its sales strategy due to stagnancy and lack of growth. “It was almost like succession planning,” says Steve Haarstad, the Enterprise Minnesota business growth consultant who worked with Gauthier.

“We needed to do something differently, and it was time for change,” Jensen says, particularly after one of the company’s largest customers underwent internal changes that led to a 60% drop in orders.

After considering contracts, territories, overall plan, and types of customers to pursue, the company decided to take a new approach and hire its own sales director, first to manage the reps and eventually to work on his own to expand the company’s customer base. Before that, Jensen had managed much of sales himself. “He’s not threatened by delegating work to others,” Haarstad says.

“This was another idea that came out of the Peer Council,” Jensen says, and it’s led to Gauthier adding customers in commercial agriculture, UTV, and air purifier markets.

A respected voice

“I’ve always been impressed with how thoughtful he is,” says Kill of Jensen, who served on Enterprise Minnesota’s board for seven years, including as board chair, and has been an advocate for manufacturing with the state Legislature. “Mike thinks before he speaks, regardless of what you ask,” Kill says. “If you ask him to help with something, he won’t say yes right away. He first asks what you’re trying to accomplish and frames an answer around that. He asks good questions.”

“He’s really grown into being a true leader,” Kill adds, citing Jensen’s willingness to extend his term on the board during the pandemic and his advocacy for the state’s Small Business Grant at the Legislature in 2023. The program gives small manufacturers with 35 employees or fewer a partial rebate for participating in services to grow their business. Gauthier is too large to benefit from the program, but Jensen saw it as key to the future of manufacturing in the state.

“Like everybody, I struggle with the regulations and laws we have to live by today,” Jensen says. “I like to give legislators my perspective. What they do with it, that’s up to them.”

“Mike has been a respected voice for the industry,” Kill says. “He thinks bigger than his role at Gauthier.”

“Our employees are the key assets of our business,” Jensen says. “We want to see the company grow and employees prosper as a result. I believe in surrounding ourselves with good people and keeping a positive culture. You can throw anything at this group — there’s not much they can’t handle.”

Return to the Summer 2024 issue of Enterprise Minnesota® magazine.