A partial church pew in the entry of Northern Woodwork, Inc. (NWI) provides a reminder of the company’s beginnings in 1920. The three-ply oak pew dates back to when NWI built windows and sashes, pews, altars, and did custom milling. Owner Corey Teie says the pew end came from Trinity Lutheran Church in Thief River Falls. Since that pew was built, NWI has seen a continuous evolution of ownership, craftsmanship, products, and markets.

Teie joined Northern Woodwork in 1992, fresh from a post-high school job in a parts store in Thief River Falls. He wanted something better. He started at NWI with no background in carpentry, but after he’d been there for two years, his boss, Art Tranby, offered to put him through the Architectural Technology & Design program at Northland College.

Teie took classes during the day, then went directly to work, managing NWI’s late shift from 4:00 p.m. – 11:30 p.m. to support his wife and three kids. Most nights, his wife brought the kids by with dinner for him. It was the only family time they could find together during the week.A group of six craftsmen had incorporated to form the business in 1996, initially describing it as a manufacturer of “fixtures, furniture, building material and all other manner of articles partly or wholly wood.” As the business evolved, NWI expanded from hardwoods to work with everything from particle substrates and laminates to acrylics, metals, quartz, and just about anything else in an architect’s specs.

The company produces high quality, custom commercial work from a 30,000-square-foot facility. NWI works with major contractors for public and commercial buildings across Minnesota, North Dakota, and parts of South Dakota and Wisconsin. They build cabinetry for hospitals and offices; cubby-holes, lockers, and workspaces for schools and libraries; eating bars and breakroom centers, dramatic entryways, light sconces, metal-wrapped columns — even bullet-proof judges’ benches, jury boxes, and council seating for courtrooms and meeting chambers.

Ownership of the company has changed several times since 1920. In 1945, Howard Hoel, Sr., and his son Howard, Jr., acquired controlling interest in the business. Over the next few years, other stockholders came and went until Art Tranby and Bill Ness purchased NWI in 1981. By that time, virtually all of the company’s business was obtained through bids with major contractors. When Tranby and Ness decided to sell in 1996, a year after NWI was named Thief River’s Business of the Year, Teie and five other employees bought the company, coming full circle to another six-member ownership team. In the past few years, one owner passed away and four others sold their shares as they retired. When Teie bought out the last of the five in 2022, his son Cody bought into the company.

Cody started working with NWI as a high school senior in 2010, and has climbed the ranks much as his father did — starting on the shop floor and working his way up. Today he is NWI’s main saw operator and plant manager.

Bill Martinson, a business development consultant at Enterprise Minnesota, has worked with NWI over the years and notes the consistency of quality and longevity of craftsmen. He says the company keeps up to date with the best machinery and delivers on time. “A company has to be good to get the bids NWI gets,” Martinson says, “and they are.”

Teie credits the company’s employees for its success. Now in his 32nd year at NWI, he has two employees with even longer tenures: one in his 42nd year and another in his 34th. The last partner Teie bought out had been with NWI for 38 years.

Most of the people who come work at NWI enter with no carpentry background, Teie says. “So we train everything.” New hires start out on the production floor, as he did over three decades ago. “We have a 90-day rule, but if I see somebody who is working extremely well within the first two weeks, I’ll give that person a raise right away.”

Cody describes his dad as “a laid-back guy who gets things done.”

“I don’t micro-manage,” his dad says. “I trust my employees to do their work; they know their jobs. I point them in a direction, and they follow through.”

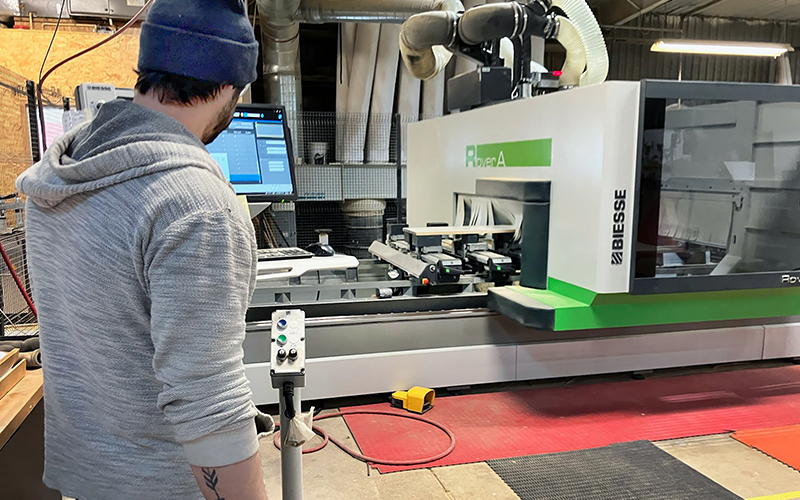

Today’s high tech machines help offset labor shortage issues; they cut, drill, glue, and edge boards quickly and efficiently. Every board that comes off the main saw is labeled with a bar code. Parts then go to a CNC machine, where the operator scans a code that pinpointedly prescribes all the drilling needed on each piece. A dowel system is used to put cabinets together. A dowel inserter injects glue and then shoots a dowel into each hole. Cody foresees additional automation in the future, particularly as the company’s production continues to grow and laborers become more difficult to find.

The company has seen continued growth, with 2023 one of their best years yet. “You have to grow a little bit every year, otherwise it doesn’t work,” Teie says. The plant’s site has enough space to add another 5,000 square feet if needed. “We can spend the money and add on,” Teie says, “but employment issues are the most challenging right now.”

Currently, NWI has 21 employees producing more than 40 workers could in past years, but Teie could use another estimator and another saw operator.

March through August are especially busy. Schools have only two and a half months in the summertime to get things done, Teie says. Last summer was NWI’s busiest ever. “We worked seven days a week all summer.” The company doesn’t have mandatory overtime, so Teie was often in the shop himself. He still loves the hands-on part of the job.

“We have a lot of schools lined up this summer already — five in Mankato alone and two or three other school projects, so we’re pretty full through August right now.”

The start of 2024, he says, is even better than 2023.

Return to the Summer 2024 issue of Enterprise Minnesota® magazine.