Eric Blaha grew up on a hobby farm in bucolic Verndale, Minn. And while he’ll probably always have farming in his blood, he knew by the time he graduated that he was born to be an engineer.

He also knew that, in addition to his studies at North Dakota State University, he’d need practical experience. He worried, though, that he’d need to travel to a bigger city to get that experience — something he wasn’t quite keen on.

So, he started looking around for internship opportunities, hoping to find something close to home. That’s when he found a program called SciTech, a nonprofit that acts as a pipeline between college STEM majors looking for internship experience and small businesses that need and want extra help. SciTech connected Blaha with Kit Masters, a manufacturer of fan clutches in Perham, a 40-minute drive from Verndale.

“I thought I had to work in a big city to be an engineer,” he admits. “SciTech showed me that small towns offer real career opportunities. It gave me valuable insights and showed me industries I hadn’t considered.”

Since its inception in 2011, SciTech has done for 3,400 college students exactly what it did for Blaha. But now all that work in lining up students with opportunities may come to an end.

SciTech’s operating budget came largely from a state grant. And while it lobbied this year for another two-year allotment of about $1 million, their request was unexpectedly denied, leaving the program’s future uncertain.

The program works by offering wage reimbursement grants. This allows manufacturers to add top-tier STEM talent at a reduced cost, and an inside track at hiring the students as full-time employees upon graduation. Using a streamlined application process that vets all applicants, SciTech has placed students with manufacturers in 150 cities across the state.

“We’re not just an IT program,” says Piper Cleaveland, SciTech’s program director. “We work across multiple industries — from manufacturing and medical devices to solar technology and beyond.”

The program’s reach extends beyond simple job placement, creating pathways for meaningful career development and local talent retention.

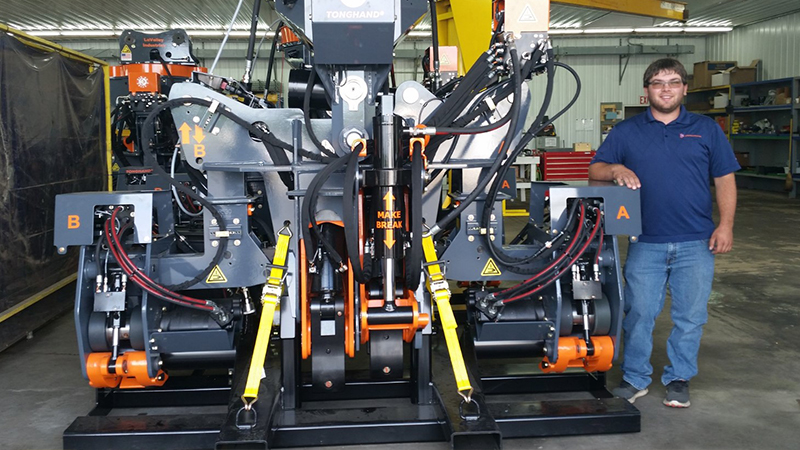

LaValley Industries, Cleaveland says, is a prime example. A student intern there helped design a massive industrial crane attachment, moving from computer-aided design to actually building the prototype during subsequent internships. Such experiences demonstrate the program’s tangible impact on both students and businesses.

The current funding crisis threatens to dismantle this successful model. With the program’s future uncertain, SciTech is exploring creative solutions. Potential strategies include finding a new organizational home, potentially with a chamber of commerce or workforce development organization, and potentially scaling back operations.

Currently operating with just one full-time staff member and supported by the Minnesota Technology Association, SciTech placed 255 students last year and is on track to place 325 this year. Cleaveland says the potential loss of SciTech could significantly impact Minnesota’s ability to retain and develop local STEM talent.

The funding shift reflects broader changes in workforce development funding. Cleaveland says legislators are moving away from direct appropriations, preferring competitive grant models and focusing more on early-stage education initiatives. This approach, she says, potentially overlooks the critical role programs like SciTech play in connecting college students with meaningful professional opportunities.

For businesses like Pequot Manufacturing, which has consistently utilized SciTech’s services, the potential program closure represents a significant disruption to their talent acquisition strategies.

Glen Young, director of support operations at Pequot Manufacturing, says internships there are more than just summer jobs — they’re critical pathways to developing the next generation of skilled manufacturing professionals. With 220 employees and a commitment to nurturing local talent, the company has leveraged the SciTech program to create meaningful learning experiences for engineering and technical students.

“We try to offer opportunities first to local kids who have been scholarship recipients,” says Young. “We don’t just look at interns as cheap help but consciously expose them to different manufacturing disciplines.”

The internship model at Pequot is strategic and comprehensive. Engineering students typically spend their first year on the shop floor, gaining hands-on experience across various manufacturing processes. In subsequent years, they work directly with engineering, R&D, and automation teams.

Particularly on the machining side, Young says Pequot internships function almost like an apprenticeship. First-year students learn basic skills like part handling, while second-year participants tackle more complex tasks. For technical school students, this approach has been remarkably effective, with Young noting that on the machining side, “it would be rare that the machining interns didn’t stay with us, whereas the engineering interns might work for someone who may outsource their projects to us.”

The SciTech program’s cost-sharing model has been crucial in making these internships viable. By offsetting wage expenses, companies like Pequot can take on more students than their budget might typically allow.

“With the SciTech approach of sharing the cost, we might take on more interns than we would otherwise,” says Young.

Dawn Loberg, a business development consultant for Enterprise Minnesota, says losing a successful school-to-business pipeline such as SciTech is regrettable.

“In this era, it’s hard to find good, qualified workers,” Loberg says. “It seems counterproductive for the state to not fund a program that works with people in the trade schools to help them go into manufacturing and really see what it’s like to create that partnership between the student, the government, and the manufacturer. We keep preaching that manufacturers really should partner with technical schools, and then we cut this program?”

Cleaveland hasn’t given up hope just yet. She says SciTech is looking for ways to continue what they consider a valuable program, especially for small- and medium-sized manufacturers.

“We have a couple of maybes,” she says. “So, we’ll see what happens. We’re keeping our fingers crossed.”

Hopefully, the success stories of students who used their SciTech opportunity to launch their careers can sway some of those maybes.

Blaha is a perfect example. He parlayed his experience at Kit Masters, where he learned valuable tools that helped him land his next job.

After several years of employment by manufacturers, he eventually landed a job as a consultant for Enterprise Minnesota, a place where he can use his experience and practical knowledge to help other manufacturers maximize efficiency and profitability.

“SciTech broadened my horizons to what was out there for different manufacturers and different places of work,” he says. “I wanted to try and live at home for another year, save some money on rent and living expenses. And because of SciTech, I was able to do that.”

Return to the Fall 2025 issue of Enterprise Minnesota® magazine.